SERVICES Advance NDT

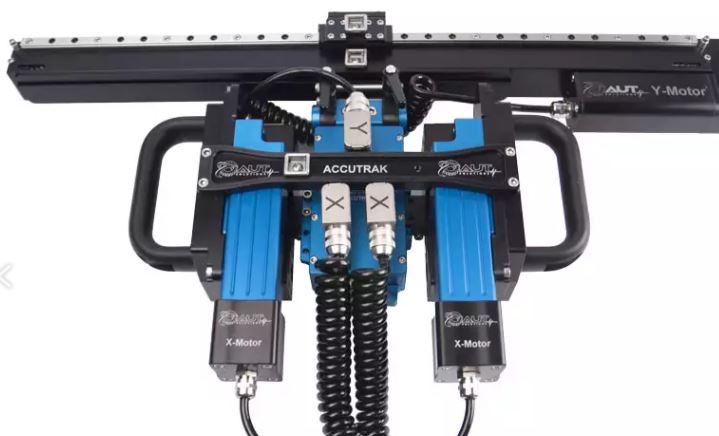

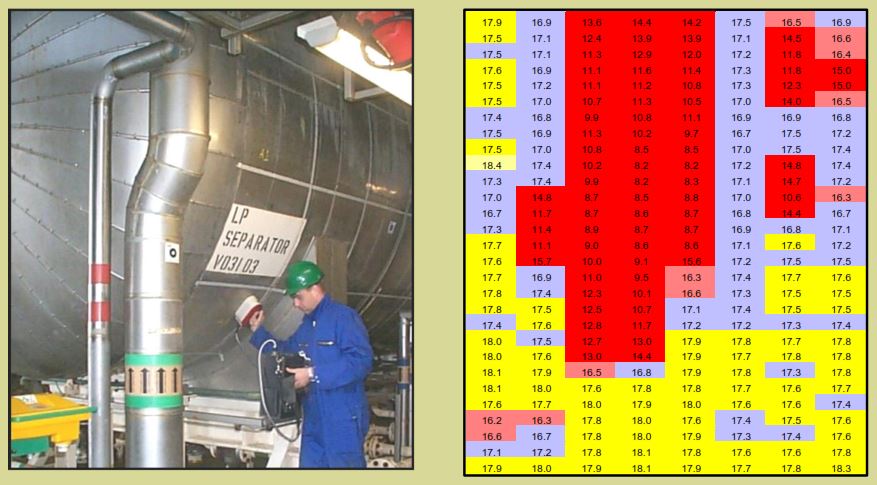

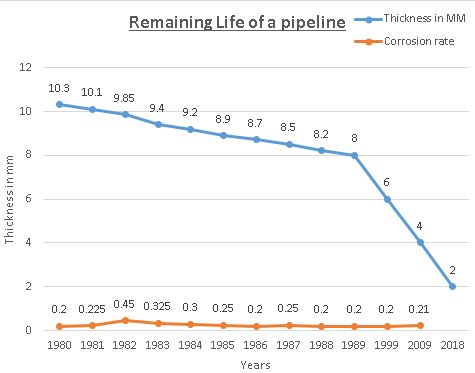

Automated Corrosion mapping is the best tool for quick inspection of the Tank Shell walls, Pressure vessels and Pipelines.

ROV Tools for internal tank inspection used while the tank is in service have been developed. These robotic crawler devices are designed for total immersion in liquids and have been successful in providing ultrasonic thickness information on tank bottoms in clear finished product storage such as gasoline, naphtha, jet fuel, No. 4 and No. 6 fuel oils, condensate

and some crude oil.

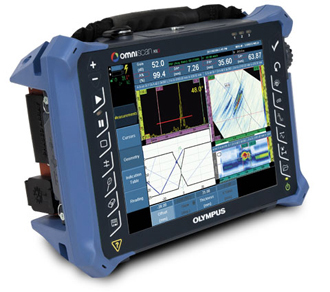

Advance Ultrasonic inspection like Phased Array and TOFD (Time of Flight Diffraction) are considered as one of the best acceptable Advance NDT techniques in modern day. There are wide applications of this technique in inspection field, namely HTHA (High Temperature Hydrogen Attack), Weld Inspection, Pressure vessels, Flange condition monitoring, Anchor bolts inspection, etc.

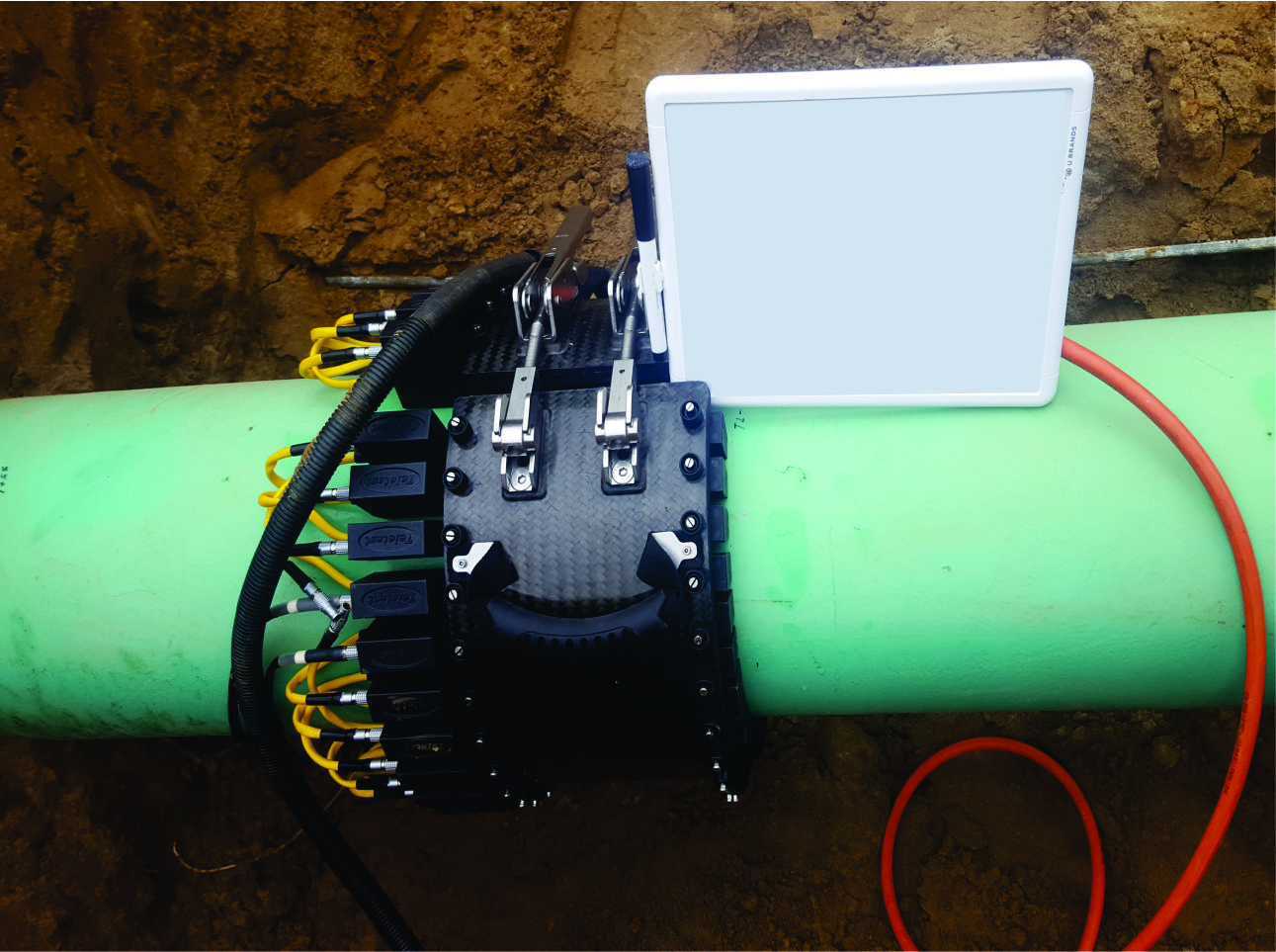

LRUT offers 100% pipeline screening at an optimum speed to check integrity. LRUT is widely accepted technique for unaccessible areas of the pipe sections such as underground piping, road crossing, culverts, insulated piping, risers, above ground piping,etc.

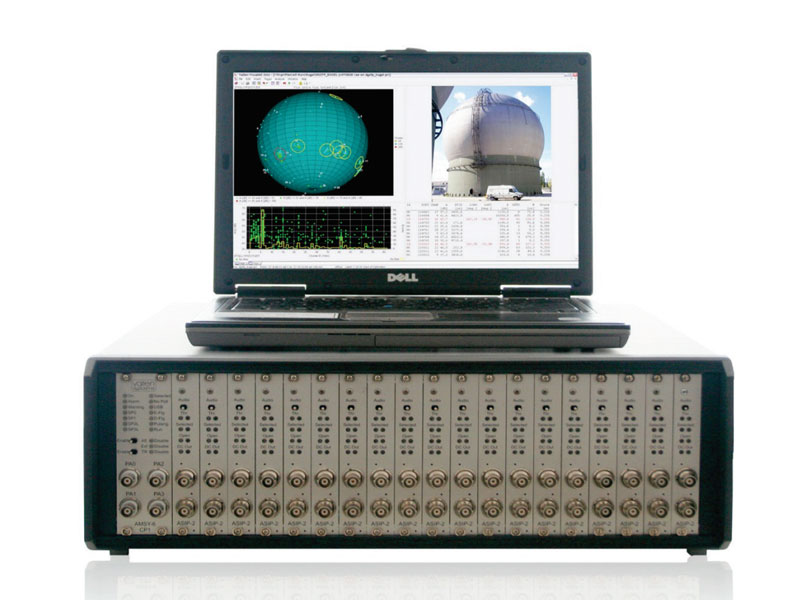

Acoustic Emission Testing is yet another screening tool or life extension tool accepted world wide. Acoustic Emission Testing has wide range of applications for identifying active corrosion, leaks and growing cracks mainly. Major applications includes Storage Tank bottom plate inspection, Pressure proof testing of Piping systems and Pressure vessels (Metal and GRE), cylinders, cranes, spheres, etc.

Short Range Guided Wave Testing as the name suggests is used for identifying percentage metal loss for the inaccessible areas of the equipment under inspection. The major applications are Storage Tank annular ring, area under pipe support/saddle, area under pressure vessel supports, etc.

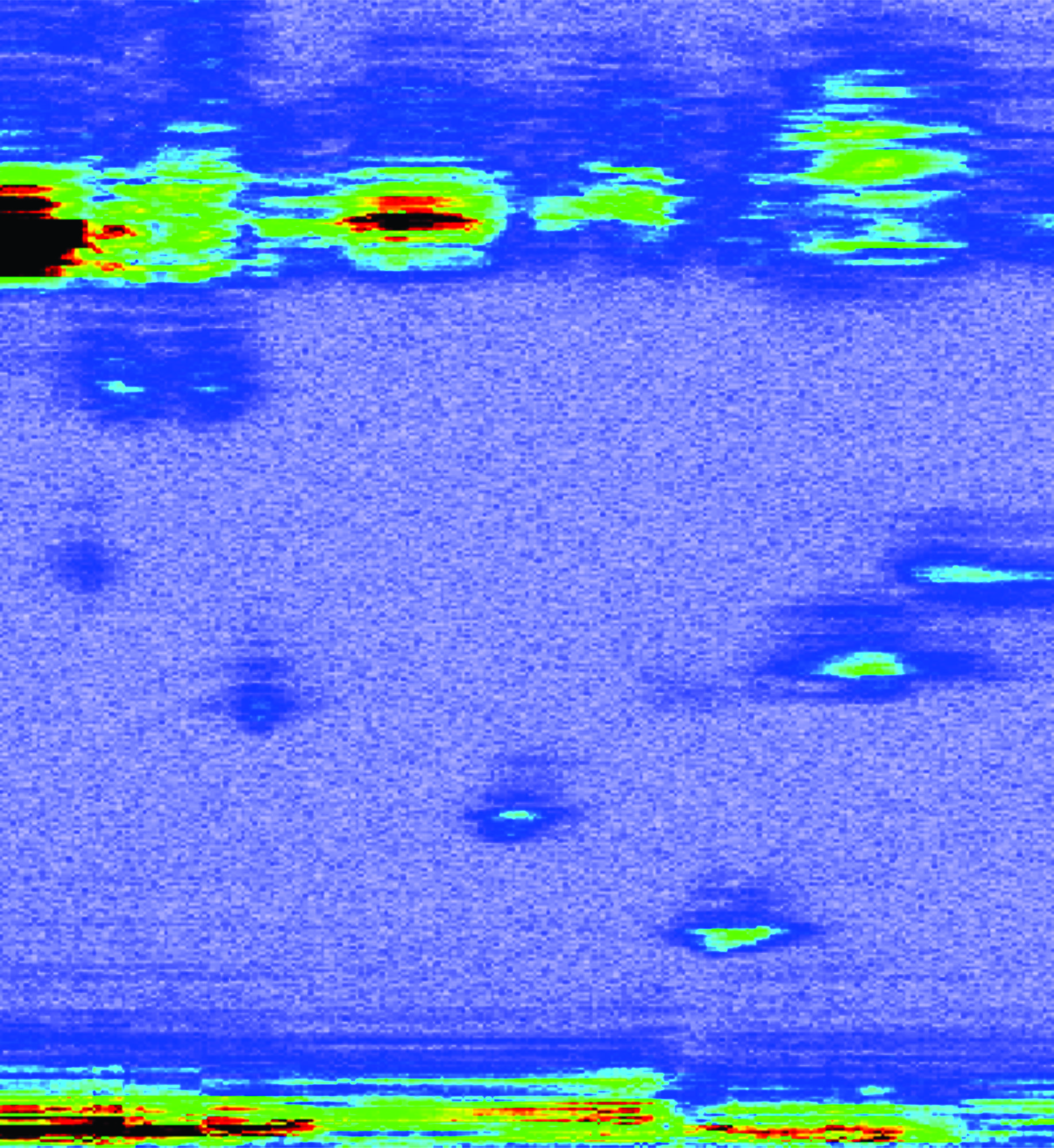

Pulsed Eddy current technique was developed to find corrosion under the insulation without removing it. This technique gives an average footprint and percentage wall loss. It is used as screening tool for inspection of the insulated pipe, pressure vessels, tanks, sphere legs, sub-sea Riser legs, Fire proof coated metal legs, etc.

SERVICES INSPECTION ENGINEERING

We provide one of the best API 653, 570, 510 Inspection services, followed by RLA and FFS (Fitness for Services). A complete package to your inspection and Engineering needs.